GARANT Master Steel range – experts for drilling steel

The GARANT Master Steel family is characterised by particularly high process reliability and performance for drilling applications. The series offers the optimum drill for every machining task in steel – both generalists and specialists for deep hole drilling or micro drilling, making it possible to master even these particular applications with ease.

The GARANT Master Steel solid carbide drill bits:

Discover all the GARANT Master Steel drills

GARANT Master Steel FEED

GARANT Master Steel SPEED

GARANT Master Steel DEEP

GARANT Master Steel solid carbide reamer

GARANT Master Steel MICRO solid carbide drill

GARANT Master Steel HPC drill

Absolute power: GARANT Master Steel Feed is setting standards for feed performance and tool life

With its three cutting edges, the GARANT Master Steel Feed high feed rate drill has clear advantages in applications requiring maximum performance. Thanks to its innovative triple-edge point geometry and optimised design for a maximum feed rate, this high-end drill is setting the new standard for its class.

When processing steel on machines with a high spindle power and torque, the GARANT Master Steel FEED achieves a previously unattained metal removal rate. With its two-stage point geometry, the tool offers very good centring capability, enables spot drilling on slightly irregular surfaces and achieves absolute extreme values for feed and tool life. For machines with stable operating conditions and high power consumption. For absolute productivity and maximum performance. Suitable for components with critical irregular surfaces thanks to its outstanding spot drilling behaviour. For diameter range from 4 mm to 20 mm.

1. Three cutting edges with special point geometry

- Stable cutting edges with large clearance at the centre

- Designed for maximum feed rates

2. Optimised point geometry with 145° point angle

- Very good chip flow with reduced cutting pressure and controlled chip breaking

- Reduced flashing when drilling through holes

- Guarantees long tool life and process reliability

- Patent pending

3. Specially developed chisel point

- Outstanding self-centring, enabling easy spot drilling even on critical and irregular surfaces

4. Coating

- Multi-layer PVD coating with nanolayer structure for even, controlled wear behaviour and long tool life

5. Solid carbide substrate

- Greatly improved bending strength and hardness properties

6. Three guide chamfers

- Stable guidance in the bore and at the drill exit

- Exact roundness and compliance with bore tolerance

GARANT Master Steel Speed

Extreme speed for maximum efficiency: GARANT Master Steel Speed defines cutting speed

The GARANT Master Steel Speed high-speed drill is more than just another high-performance tool. Thanks to new features and its design for maximum speed, the high-end drill achieves a previously unattained metal removal rate. You will achieve maximum efficiency when processing steel on machines with low spindle power but high speed and for components with thin cross-sections. An innovative new carbide substrate. The special arrangement of the four guide chamfers and a first-rate coating enable extreme cutting speeds and great durability. Ideal for machines with high speed and low power consumption. The GARANT Master Steel can be used with and without through-coolant (Art. No. 12 2415). Due to its low cutting forces, it is suitable for thin and unstable components. For diameters ranging from 2 mm to 20 mm.

1. Low front middle position of the main cutting edge

- Cutting forces significantly reduced during drilling

- Outstanding drilling performance even at high cutting speeds

2. Slim chisel point

- Perfect self-centring upon drill entry

- The material is cut virtually to the middle and not displaced as in the usual chisel point design

3. Coating

- Wear resistance, even at high process temperatures

4. Special guide chamfers

- Reliable tool guidance as the second guide chamfer supports the drill at an early stage

- This ensures maximum straightness and quality in terms of the hole diameter

5. Optimised solid carbide substrate

- Extreme hardness, specifically to withstand very tough conditions

6. Polished flutes

- For the highest demands regarding the bore surface quality

- Optimum chip flow at high machining volume

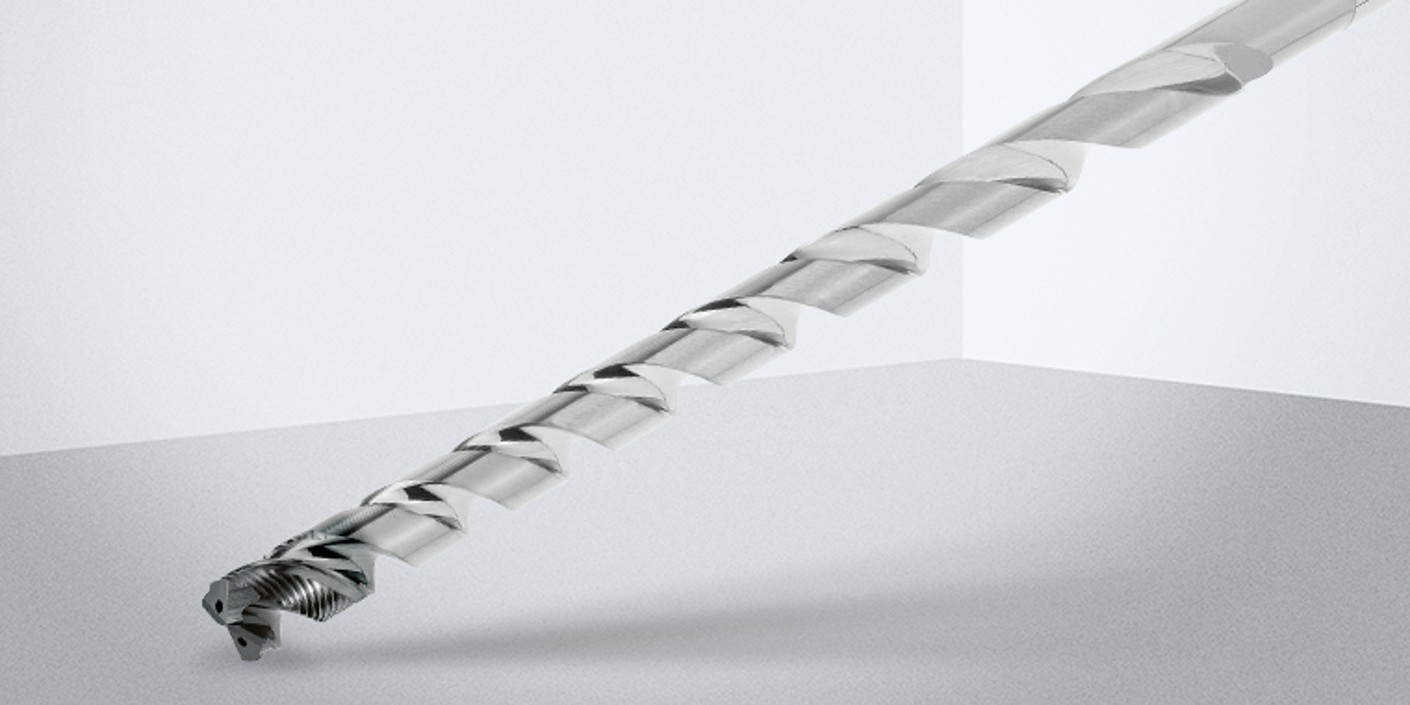

GARANT Master Steel Deep

Creative innovation meets technical perfection

GARANT Master Steel Deep is the ultimate solution for deep hole drilling. It offers a large number of technical highlights to meet the challenges of deep hole drilling without problems:

- Maximum cost-efficiency

- Very high productivity

- Very high process reliability and precision

- Extremely long tool life

In direct comparison with competitor products, the GARANT deep hole drill masters every challenge with impressive performance data:

- Cool head thanks to helical through-coolant in the area of the drill tip

- Very high stability – extremely robust, sintered carbide substrate (patented)

- Very long tool life due to TiAlN multi-layer coating

- Extra feed rate due to straight main cutting edges

- Lapping so that everything runs smoothly

- Extremely dynamic – central through-coolant meets helical coolant holes

- Adaptive helix angle 30° – 15°

- Precise drilling due to a combination of guide rings and guide chamfers (patented)

GARANT Master Steel Micro stepped drill

One tool – two applications: solid carbide step drills for drilling on inclined and curved surfaces

The solid carbide pilot drill can handle drilling on both inclined and curved surfaces. With its short, stable cutting edge, it can drill with exceptional process stability and is ideal as a pilot drill for the Master Steel Micro. Drill sizes: Ø 0.8–3 mm.

- Tip angle 160°

- Straight main cutting edge, 4-sided grinding

- Cutting edge 90° countersink

- Reinforced shank construction

- Carbide (10% cobalt)

Drilling on differently shaped surfaces

Drilling on curved surfaces

GARANT Master Steel Micro

A high-performance micro-drill

GARANT Master Steel MICRO solid carbide drill – a high-performance micro-drill for universal material use, focusing on steel processing. Once a pilot hole has been drilled, the maximum process reliability ensured by exactly matched tools within the overall system and the expanded guide chamfer make it possible to drill holes of very small diameter down to the maximum depth. This produces the ideal compromise between core diameter and flute size for optimum chip evacuation – even with long-chipping materials.

Even when working with the very small hole diameters combined with a large L/D ratio, the increased metal removal rate and longer tool life ensure an economical drilling process.

- Maximum process reliability thanks to harmonised tool system and extended guide chamfer

- Precision drilling of the smallest diameters up to the maximum depth after pilot drilling

- Optimised geometry for ideal chip removal - even in difficult materials

- High economic efficiency thanks to increased metal removal rates and long tool life

- Reliable with a large L/D ratio even with the smallest drilling diameters

GARANT Master Steel solid carbide reamer

The latest generation of universal HPC reamers.

They can be used without compromise for steel and stainless steel thanks to their extra-short cutting edges and optimized cooling strategy with radially arranged coolant outlets aligned directly with the cutting edges. This ensures the reliable processing of high-strength steels up to 60 HRC.

- Version suitable for NC with straight shank diameter for standard holders, especially in hydraulic chucks or high-precision collet chucks.

- Very high concentricity and process reliability due to unequal spacing.

GARANT Master Steel HPC drill

Masterful performance in steel

The latest technology meets the tried-and-tested sturdiness and reliability of a convex cutting edge. The unique combination of drill point geometry and TiAlN special coating was developed specifically to meet the requirements of steel. This permits the efficient machining of steel with maximum precision.

The solid drill body ensures higher feed rates without compromising on tool life. The convex cutting edges guarantee maximum robustness, even when processing steel with a tensile strength up to 1400 N – a key advantage for demanding applications. The special cone shape improves the stability of the cutting edge to allow precise drilling and clean cutting. And the optimised flute geometry ensures reliable chip evacuation.

The portfolio:

- Diameter range: 3mm* to 20mm

- Types:

- 4×D without through-coolant (12 2470)

- 4×D with through-coolant (12 2475)

- 6×D with through-coolant (12 2761)

- Convenient tool upgrade as the dimensions and list price are the same as the old tool.

*Use the GARANT Master Steel MICRO solid carbide micro-drill for the efficient machining of steel in diameters ranging from 0.8 mm to 3 mm.