Perfect cuts from the very outset – get optimum machining results with our saws.

Simply perfect sawing. The first step in increasing productivity.

You already know that we provide the very best machining tools. But did you also know that we offer a wide selection of high-quality saws as well as a regrinding service for circular saw blades?

Why buy saws from us? – Because we make things efficient and straightforward – as they should be!

Save time, hassle and money:

- Save time: Simply order your saws together with your machining tools and save precious time. There’s no need to place additional orders with other suppliers – you get everything in one package.

- A single point of contact: Spend less time communicating with different people and reduce the risk of chaotic communications. You have a single point of contact for all your tooling needs, meaning your ordering process becomes much simpler.

- Advice that isn’t tied to a specific brand: We provide bespoke on-site advice that is completely independent of specific brands and suppliers. Our aim is quite simple: To make you as our customer even better!

- A faster process: By bundling your orders with us, you benefit from a faster and more efficient process.

- Quality and reliability: Just like our machining tools, our saws are synonymous with the highest quality and reliability.

- Regrinding for improved performance: If a saw blade is no longer in top condition, simply send it in to us for regrinding. Your tool will then perform well for many years to come and you can save up to 85% of the costs!

To the regrinding service

Our sawing portfolio in the eShop

Go to the sawing range

Sawing raw material: Cutting raw material to length

Everything you need to know about cutting raw materials to length

- Bandsaws

- Circular saws

Cutting on the lathe or milling machine

Everything you need to know about parting off components.

- DIN circular saw blade

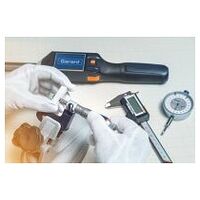

- GARANT sawing system

- Mimatic sawing system

Services

Everything you need to know about reconditioning your tools.

- Regrinding

- Coating

- Tool search with ToolScout

Initial overview: General advantages and disadvantages of bandsaws and circular saws

Bandsaw

| Advantages | Disadvantages |

|---|---|

|

|

Circular saw

| Advantages | Disadvantages |

|---|---|

|

|

Bandsaws for versatility and precision

Bandsaws are essential metalworking tools and impress with their flexibility and versatility. They are suitable for cutting a wide range of different metals, from aluminium alloys to high-strength steels and titanium. They enable fast, precise cuts thanks to their endless rotating blade and sharp teeth. If you choose the right toothing and cutting parameters, they can be used for both coarse and fine cuts. Bandsaws are a cost-efficient solution in many industrial manufacturing processes, both for series production and when working on individual workpieces.

Expert tip:The working life of a bandsaw blade is to a large extent dependant on controlled running in. At normal feed rates the sharp teeth of a new blade dig very aggressively into the material. Therefore, the feed rate should be reduced by 50% for the first cuts. After the blade has cut an area of about 300 cm2, the feed rate can be slowly increased to the optimum value.

Attention: Simply get in touch if you need a specific length of saw blade (as from M42). You can, of course, configure the bandsaw blades in line with your specific needs.

When placing an enquiry, please state the bandsaw machine (manufacturer and type), blade dimensions, material and material cross-section. Our application engineers will gladly offer you further technical advice.

Reasons why bandsaws may fail and remedies

Fault: Teeth become dull too quickly

Cause:

Cutting speed too high, cooling insufficient.Remedy:

Use lower cutting speed, ensure good cooling.Fault: Teeth break off when cutting profiles

Cause:

Tooth pitch too coarse / incorrect tooth geometry.

Cutting pressure too high.

Workpiece not clamped securely.Remedy:

Adjust the tooth pitch and tooth geometry.

Reduce the cutting pressure.

Securely clamp the workpiece.Fault: Teeth break off when cutting solid material

Cause:

Tooth pitch too fine.

Cutting pressure too high.

Workpiece is not clamped securely.Remedy:

Use larger tooth pitch.

Reduce cutting pressure or use higher cutting speed if possible.Fault: Blade breaks at the weld seam

Cause:

One or both guides are not perpendicular to the vice support.

One of the two back rollers does not lie against the blade back during the sawing process.

Blade tension too high or too low.

Crooked cut.Remedy:

Align the guides using a try square when the blade is tensioned.

Adjust the blade back guide.

Observe the machine manufacturer’s instructions to achieve correct blade tension.

See crooked cut fault.Wear characteristics on the bandsaw blade and their cause

Wear characteristic: Running marks caused by the blade side guides

Cause:

The blade side guides (usually carbide parts) are worn. One or several wear marks are created regularly. If a wear mark was created only once with only one

bandsaw blade, the cause was a trapped chip (e.g. between the blade and the side guide).

Cracks along the entire blade back edge leading to blade breakage at any point

Cause:

The blade runs against the collar of the drive wheel and/or deflection wheel. Can be checked using the “paper test” – performed by RÖNTGEN-AT. The wheels need to be adjusted. The blade back guide is worn.

Wear characteristic: Pronounced burrs over the entire blade back edge.

Cause:

- All tooth tips are still well formed / sharp:

Blade back guide worn.

- All tooth tips are heavily rounded / worn:

The burr has been created because chips are no longer being produced and the bandsaw blade back edge has therefore been pressed strongly against the blade back guides.

- Cause of rounding:

Tooth pitch is too fine for the material cross-section. Cutting pressure too high, cutting speed too high.

Wear characteristic: Blade split lengthwise.

Cause:

- At least one damping roller is incorrectly positioned or worn.

- A ball bearing (damping roller) is blocked. Corners/edges are rubbing against the blade.

- The blade is split because the bearing is harder than the blade.

Wear characteristic: Tooth tip chipping, tooth breakage

Cause:

Vibrations, chopping and tearing have occurred.

Causes: Tooth pitch too large. Cutting speed

too high. Moving guide arm not adjusted.

Workpiece loose, not sufficiently clamped.

Wear characteristic: Strongly rounded tooth tips

Cause:

- Cutting speed too high.

- Cutting pressure very low.

- Tooth pitch too fine.

Wear characteristic: Cracked weld seam

Cause:

The crack in the blade propagates as a “zigzag”. The blade has obviously been in use for a long time: Tooth tip wear, eroded chip grooves, shiny

running marks evident.

This is an overload breakage. This was caused by worn machine components. Additional wear characteristics can be seen on the blade.

Smooth bursting of the weld seam. All tooth tips are almost as new. The blade only ran for a short time.

This may be a manufacturing defect.

Wear characteristic: Bandsaw blade is heavily deformed

Cause:

Check the position of:- Drive wheel, deflection wheel

- Damping roller

- Both blade side guides.

Wear characteristic: Problems based on material condition

Cause:

Poor material can cause a hollow, bulbous section, crooked cut, tooth tip breakage.

Hard spots, voids, surface scale, far higher tensile strength than indicated could be the cause.

In general: The machining parameters must be adjusted in line with the material quality and material characteristics.Bandsaws: An initial selection of bandsaw blades:

Circular saws for efficiency and speed

Circular saws are indispensable in metalworking as they enable fast and precise cuts in metals of different types and thicknesses. Their rotating saw blade mechanism ensures high cutting speeds, which is ideal for coarse cuts and fine work in series production. They are primarily used for work on profiles, tubes, sheet metal, and bar material.

Circular saws are versatile and efficient tools thanks to the wide array of saw blades, which offer different tooth geometries and fittings. They provide very accurate cuts and ensure low material deformation and a long service life, making them an essential tool in modern manufacturing processes.Troubleshooting: Faults when working with circular saws and remedies

Fault: Teeth become dull too quickly

Cause:

- Too many chips in the chip base, teeth become clogged

- Cut is not clean

- No or unsuitable cooling

Remedy:

- Select a larger tooth pitch

- Select a finer tooth pitch and reduce the cutting pressure

- Use suitable coolantFault: Teeth break off

Cause:

- Poor chip evacuation

- Teeth catch in the material

- Workpiece clamping

Remedy:

- Select a larger tooth pitch

- Select a finer tooth pitch

- Re-tighten the workpieceFault: Blade breaks

Cause:

- Incorrectly positioned when the cut starts

- Circular saw blade too dullRemedy:

- Blade must not be resting on the material when starting the cut

- Re-sharpen the bladeFault: Jammed saw blade / material adheres to saw blade

Cause:

- Incorrect feed rate

- No or unsuitable coolantRemedy:

- Increase or decrease the feed rate

- Use suitable coolantCircular saws: A selection of circular saw blades

Potential solutions in the event of difficulties/problems:

Problem: Gullets clogged

Saw blade gullets are clogged

Possible cause:

- Tooth pitch too small

- Cutting speed too highSolution:

- Reduce the number of teeth

- Reduce the revolutionsProblem: Poor-quality cuts

Problem: Poor-quality cuts

Possible cause:

- Incorrect tooth shape

- Incorrect saw parametersSolution:

- Contact our technicians

- Check the parameters according to the tableProblem: Poor cutting performance

Possible cause:

- Cutting speed too high

- Insufficient cooling lubrication

- Feed rate per tooth is incorrect

- Incorrect cutting angleSolution:

- Reduce the revolutions

- Increase / check the pressure and supply of the coolant

- Check the feed rate tables

- Check / correct the cutting angleProblem: Tooth flank material

Problem: Edge build-up on tooth flanks

Possible cause:

- Re-sharpened incorrectly

- Vibrations during sawingSolution:

- Check the re-sharpening quality

- Check workpiece clampingProblem: Tooth sides

Problem: Edge build-up on tooth sides

Possible causes:

- Insufficient cooling lubrication

- Excessive axial run-out of the saw bladeSolution:

- Increase / check the pressure and supply of the coolant

- Use a saw blade with a tight axial run-out toleranceProblem: Saw blade breaks

Problem: Saw blade breaks during the process

Possible causes:

- Working parameters too high

- Unsuitable workpiece clamping

- Uneven feed rate

- Incorrect tooth pitchSolution:

- Check the working parameters according to the table

- Check the quality and clamping force of the clamp

- Check the feed system of the sawing machine

- Check the parameters according to the tableProblem: Burns

Problem: Burns on the workpiece

Possible causes:

- Blunt saw blade

- Insufficient cooling lubricationSolution:

- Re-sharpen the circular saw blade

- Increase the pressure and supply of the coolant

Sawing instead of grooving: Our recommendations

Circular saw blades, sawing systems from GARANT and Mimatic

In the metalworking industry, circular saw blades with different tooth shapes are available to meet the different requirements for cutting speed, cutting quality and material processing.

Sawing on lathes and milling machines – the advantages:

- Cutting edge is not permanently engaged, meaning low thermal wear.

- Chips are effectively removed from the machining zone.

- Accurate cutting with large diameters.

- Special machining tasks such as producing slots or notches can be performed very easily.

Sawing on milling machines is particularly suitable for adding thin slots or for parting off finished parts.

Expert tip:

Do not use saw blades for lateral infeed. When cutting off in opposed milling, the chips form a bed in the saw cut that minimises vibrations.

Want to find out more about sawing?

For further information and comprehensive details about bandsaw blades, toothing types, tooth setting tools, circular saw blades and services, please also see our brochure:

Select pick-up location

Direct purchase

Add articles directly to the cart:Products found:

-

Article no. {{ combinedCodeWithHighlight }}Article code:EAN / GTIN:Manufacturer number:Cat. Nr.:

No products were found for your search term

Please check your entry or adjust the article number / article code

This article cannot be ordered.Services cannot be ordered without the right article. Please add the service to the desired article.Further configurations on the product detail page are necessary for this article.Please check this specification or adjust the article number / article code.Please select a specific variant.An error found the way into our system.This article is not available anymore.Login

Set commission

Your customer card

Please present the QR code at the checkout.Retrieved onHow can we help you?